Bringing True Colors to MicroLED Displays

2020/06/03

Article by Dr. Tobias Steinel and Dr. Martin Wolf

Because of their superior performance, microLEDs are often considered a disruptive technology that will revolutionize the display world once we’ve realized an economical way to mass-produce them. One important piece of the puzzle is mastering cost-effective and high-end quality control in production lines. Although it’s crucial for creating perfect displays and an impressive user experience, microLED displays’ improved optical properties pose challenges to standard measurement equipment. Here, we explore an innovative solution that addresses that concern.

Nearing a bright and truly colorful future

MicroLEDs are bright, small, and power-efficient. They promise fully immersive display resolutions and real-world color, and they help increase wearable displays’ battery lifetime. In particular, microLED technologies are expected to drive head-mounted devices for augmented and virtual reality (AR/VR) applications.

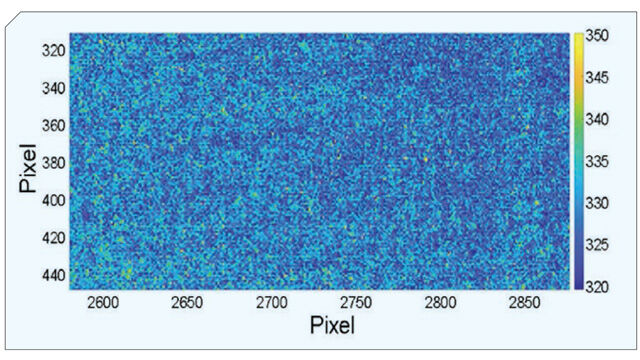

Each microLED in the millions of pixels on a display is an individual light source with individual variations in color and luminance. To produce high-quality uniform displays, these variations must be tested, corrected, and kept below visual noticeability. To assure the highest quality under the constraints of economical production takt times, fast and accurate optical testing has to be provided for every pixel on the entire display.