Precise measurement of the smallest deviations ensures accurate binning of LEDs

Today, conventional light sources have largely been replaced by LED-based light sources. In many cases multiple LEDs are installed, and as far as possible they are required to exhibit the same behavior, optically as well as electrically.

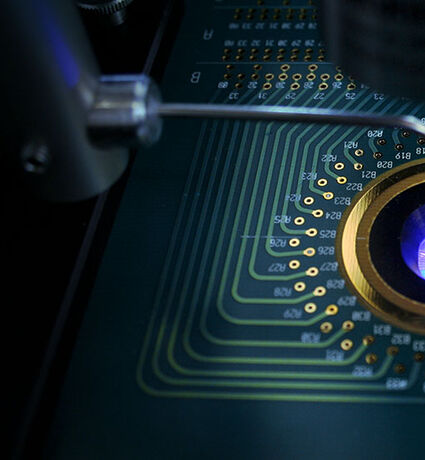

Because the properties of these semiconductor components depend, among other things, on precise setup of the layer structures and their composition, tiny deviations in the individual LEDs can have a serious impact on the optical and electrical properties of the individual LEDs. Each and every LED must be precisely characterized and subdivided into groups (bins). Depending on the manufacturer, LEDs are often subjected to several tests during their production process. This normally takes place at wafer level (wafer probing and sorting) and on the finished, saleable LED.

The challenge in LED in-process inspection

In production environments, exacting requirements are placed on measuring systems:

- High degree of reliability in 24/7 use

- Short measuring times, to achieve a high throughput

- Precise, controlled timing of measurements (triggering)

- High reproducibility of the results from system to system

- Measurement adapters specially tuned to the production process

Our solution: the CAS series of high-end array spectrometers from Instrument Systems

High-quality array spectrometers have become firmly established in the field of precise optical measurement of LEDs. The CAS 140D/CAS 120 series from Instrument Systems measures the full spectrum in one pass and derives all optical values from the spectrum. The complete optical measurement takes only a few milliseconds. Because they contain virtually no moving parts, the CAS family of spectrometers is extremely reliable and requires little maintenance.

A meticulous production process and a calibration traceable to national standards as PTB or NIST ensure comparability of the results. In addition, Instrument Systems has developed a broad portfolio of measurement adapters that satisfy the different requirements in production, together with comprehensive accessories for the complete range of production requirements.

Established cooperation with international LED manufacturers

For many years, Instrument Systems has been working together with major LED manufacturers and their integrators. The basis of LED test systems installed worldwide amounts to several thousand instruments.

Our production customers thus profit from our extensive know-how in the following areas:

- Portfolio of spectrometer measuring systems, proven for production (CAS 140D, CAS 120)

- Metrological clarification of measurement tasks

- Calibration local, offsite and onsite

- Monitoring and auditing procedures

- Provision of calibration sources

- Parallelization of measurements

- Global service network

What is your individual challenge? Together we can find the right solution – just ask us!