RC 100 Efficient production control for retroreflectors

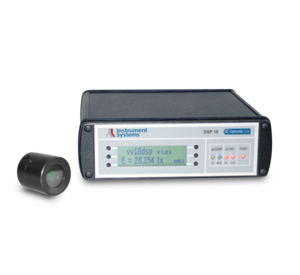

RC 100 Reflex Checker – Online - Retroreflectometer

The RC 100 Reflex Checker was specifically developed to for testing the retroreflecting characteristics of retroreflectors used in the automotive industry. The main area of application is for adjusting and monitoring injection-molding machines in production control. That way, the RC 100 is capable to replace time-consuming measurement with goniophotometers and retroreflectometers in a photometric laboratory.

The instrument comprises an optical enclosure with shortened measuring distance. The optical unit is mounted on an assembly stage with a plate height of 750 mm. This provides convenient operation of the instrument while the user is seated. The manual control panel with touch screen for setting the instrument functions is connected to the measuring unit.

RC 100 – Product details:

- Compact setup: The instrument can be placed directly in production settings thanks to the shortened measuring distance.

- Insensitive to extraneous light: The instrument can be operated under ambient light conditions due to sample illumination by a bright flash-light source, use of a triggered amplifier, and the light-shielding enclosure.

- Short measuring times: Complex setup and adjustments for the goniometer are no longer needed. The measurement is carried out in less than 0.2 seconds.

Comparative quality control of retroreflectors in production

- Measurement of retroreflectors relative to a standard retroreflector that has been calibrated in a photometric laboratory in conformity with ECE R3

- Monitoring components manufactured by injection-molding machines

- Statistical quality control during production