DMS 803 Motorized 6-axis goniometer for display measurement

Fully automatic display analysis with extensive accessories

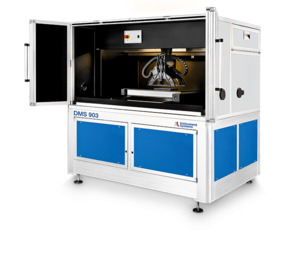

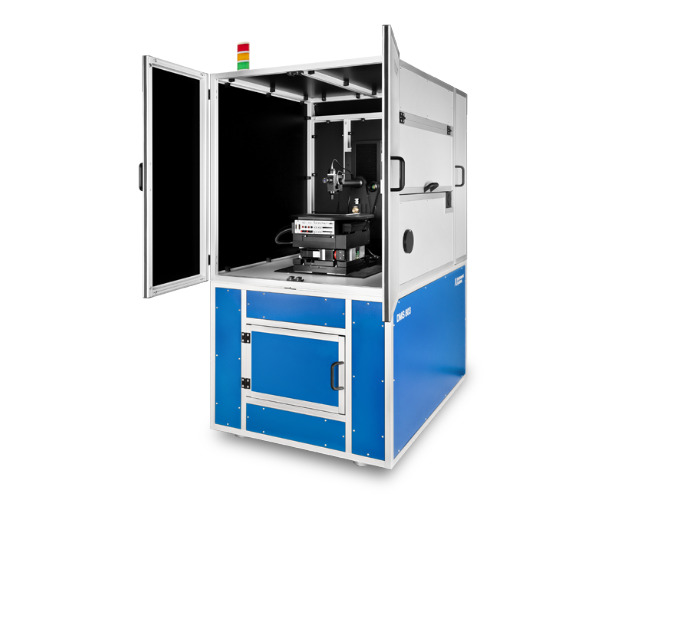

Based on a fully motorized 6-axis goniometer, the DMS 803 is used for convenient determination of the luminance, contrast and color properties of small to medium-sized displays at different viewing angles with variable electrical control.

Its scope of use embraces multiple applications in research & development and quality control. A wide range of lighting accessories and temperature control chambers make the DMS 803 particularly suitable for the characterization of displays for mobile applications (smartphone, tablet PC).

Product details:

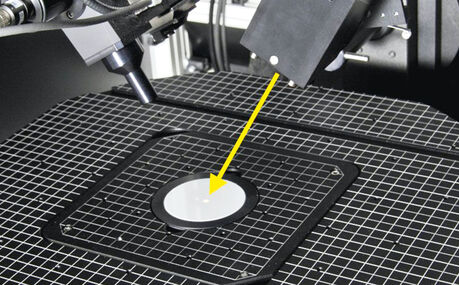

- Characterization of emissive, transmissive, reflective and transflective displays

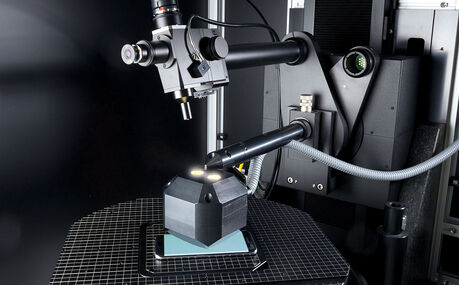

- Fully motorized 6-axis positioner with electrical control, photometer or spectroradiometer, lighting, PC and software

- Surface scan: max. 100 x 100 mm for analyzing the homogeneity of luminance, contrast and color over the surface

- Optional temperature control chamber

- Analysis of all photometric and colorimetric properties as a function of viewing angle, electrical control, temperature and time

- Extensive range of accessories for testing under varying lighting conditions and temperatures

DMS accessories

- Combined light meters: microscope, photometer, spectrometer

- Temperature control chamber

- Light sources and illumination units

- Unit for sample control

- Scan surface extension

DMS software

- Software packages DMSControl (controller) and ViPer (preparation and evaluation of readings)