Accessories DMS Complete portfolio for the characterization of displays and components

Measurement setup – maximum test capabilities!

Instrument Systems has developed a comprehensive range of accessories for its DMS systems. These include precise and fast light meters, temperature control chambers and light sources, together with positioning and control units. It represents a complete display measuring system for the full electro-optical characterization of displays in one setup.

A detailed summary of all DMS accessories incl. technical specifications can be found in the brochure DMS Series.

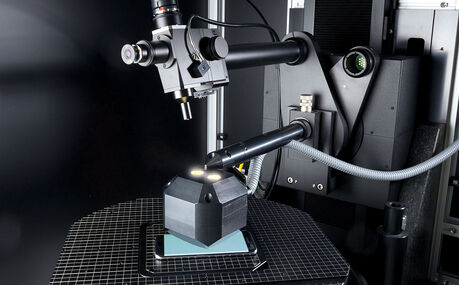

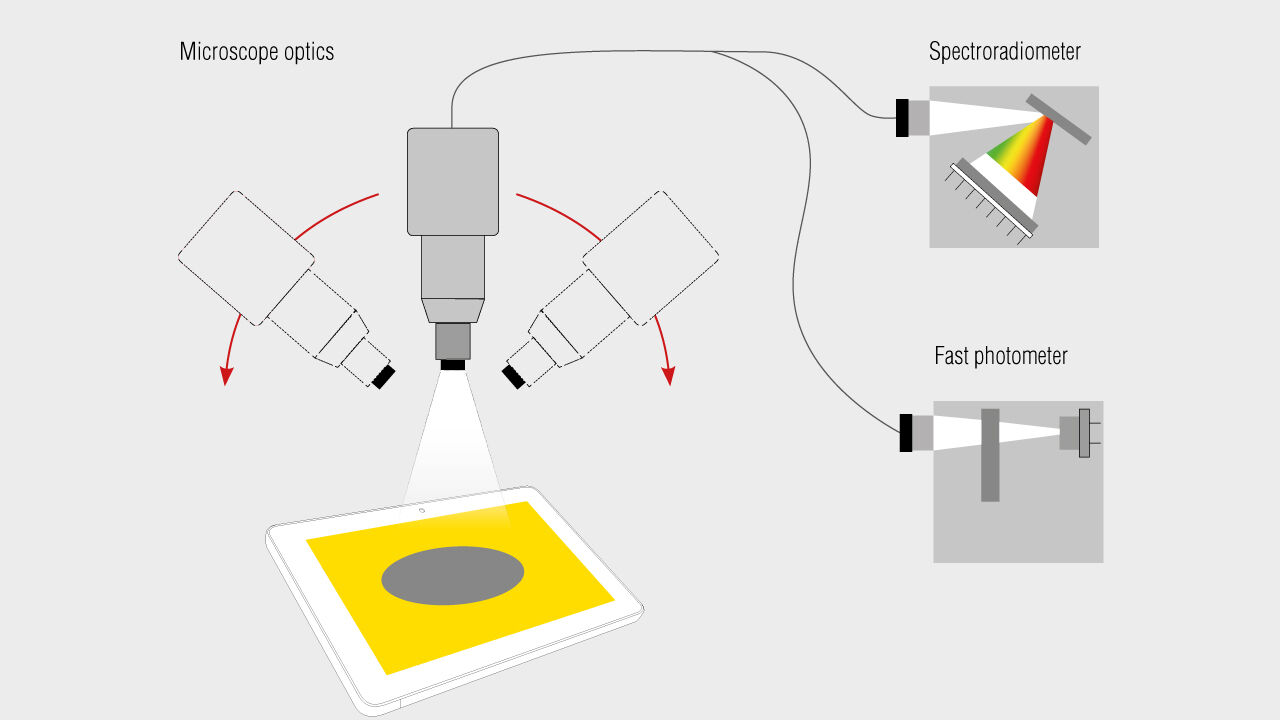

Combined light meter: microscope, photometer, spectrometer

With the combined light meters, photometric parameters and spectral distribution are determined in one measurement process. The high-end CAS 140D spectroradiometer and specially designed, high-speed photometer PMT 3 are connected by optical fibers to an optical microscope. This setup represents the human observer and ensures fast and accurate readings for any display technology.

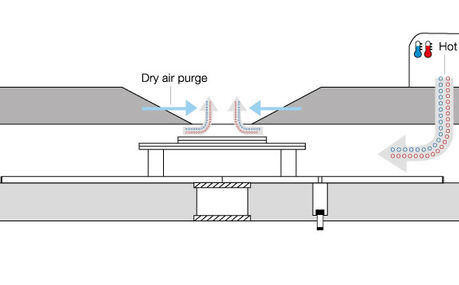

Temperature control chambers HCS series

Each DMS system can be equipped with a suitable HCS temperature control chamber for examining the temperature dependence of electrooptical properties of displays.

The test object (DUT) is exposed to a precisely controlled airstream that maintains a stable temperature at any desired level between -40°C and +105°C. All measuring instruments and mechanical components in the system remain at room temperature, leading to extremely reliable measurement results.

The temperature control chamber is available in different versions and with numerous accessories for DUT mounting and positioning with and without internal motorization.

The new extra-large HCS-7 temperature control chamber was developed specially for the new DMS 904 goniometer system and optimized for automotive applications in the measurement of extremely large and curved displays. It permits movement of the measuring instruments during the tempering process in a lateral direction (X and Z). Optimized interaction of temperature control, air flow and material properties enables high-precision angle-dependent scans along extremely long, curved displays.

Light sources and lighting units

The effect of ambient light on display properties is gaining in importance. In addition to various light sources, five different illuminating devices can be connected to the DMS systems, reflecting all relevant ambient conditions for a display:

- DHS diffusing hemisphere

- SDR integrating sphere for diffuse reflectance

- VADIS variable aperture diffuse source

- PID parallel illumination device

- PLS point light source

They simulate various different lighting conditions for the measurement of emissive, transmissive, reflective and transflective display properties

Brochure DMS Series

Application Note Reflective Illuminations

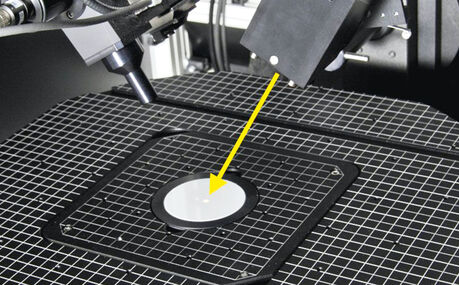

Motorized positioning unit SCAN 300

A SCAN 300 motorized positioning unit is available for systems DMS 803, DMS 505 and DMS 201. It extends the existing horizontal travel range to 300 x 300 mm. 16’’ displays can thus be covered entirely. With this extension motorized positioning and automatic scanning is possible for the manual DMS 201 system via DMS software.

Unit for sample control

Every DMS system incorporates an efficient interface as a DUT control unit. This is required for the measurement of optical parameters subject to the electro-optical operating states of the display or for conducting automatic display tests.

Components, measuring instruments or test objects with a variety of mounts and interfaces can be connected and controlled via the interface. It is compatible with analog signals, RJ45 Ethernet, RS232, USB, a 230 V power supply and SUBMIN D9 connectors. Standard signals such as HDMI or DVI can also be realized for LCD and display modules.